Strong Applicability

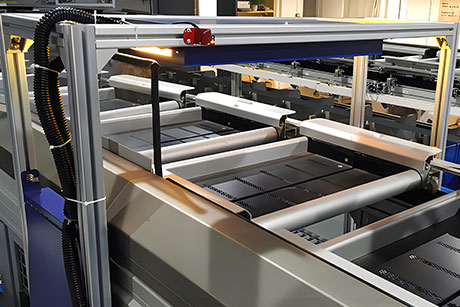

The Split Tray Sorter employs trays to carry items, making it highly adaptable for sorting lightweight, floating, or circular items that are not suitable for sorting by Cross Belt Sorters. It can sort various packaging items, including boxes, plastic bags, cartons, tote bags, and soft packaging.

Low-Speed High-Efficiency Sorting

The sorting efficiency of the double-row Split Tray Sorter with its unique "one cart, two trays" structure is twice that of a Cross Belt Sorter with the same configuration. The sorting efficiency at a ring line speed of only 1.2m/s can reach 17,280 pieces per hour. With a dual-side feeding configuration, the maximum theoretical sorting efficiency can reach 34,560 pieces per hour.

High Sorting Accuracy

Equipped with advanced algorithmic intelligent cameras, the Split Tray Sorter allows reading codes in any direction, achieving a reading rate of up to 99%. High-tech sensors and PLCs can quickly detect products and determine their path direction. The simple and agile tray manipulation mechanism ensures rapid and accurate product separation, reducing the risk of errors.

High Flexibility

The elimination of chain drive and wheel turning in the transmission system allows distributed small-power motor drives to be deployed at any node of the circular sorting system according to the terrain. The length of the sorter is almost unlimited, allowing for any number of destination paths. At the same sorting efficiency, the low-speed walking of the Split Tray Sorter is suitable for manual feeding mode without the need for a multi-level feeding system.

Small Footprint

With its unique product design, no additional multi-level feeding system is required for loading, and items can be sorted directly into bags or boxes without the need for dedicated chutes. The compact overall structure design maximizes the use of space and can be arranged around factory columns, occupying a very small overall footprint.

Low Energy Consumption, Simple Structure, Low Maintenance

Distributed low-power motor drives save energy. The unloading and resetting mechanism of the sorting cart adopts a purely mechanical structure design, with no additional energy consumption except for the main drive. The relatively low-speed operation ensures minimal wear, long service life, and low maintenance costs for the sorter.

Modular Design

The entire machine adopts standardized, modular design, supporting rapid assembly, disassembly, expansion, and relocation.

V-shaped Tray Design

The unique V-shaped tray design is capable of accommodating easily rollable items, whether they are lightweight or irregularly shaped. As long as it fits into the tray, our split tray sorter can handle sorting it.

Heavy-duty Tray Option

Our heavy-duty trays are specifically designed for demanding postal and courier environments, capable of withstanding heavy loads with each tray accommodating up to 15 kilograms.

Merging Tray Technology

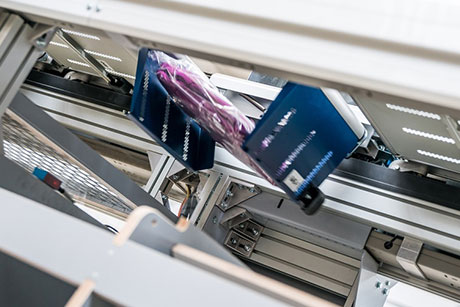

Our patented double-row tray design allows two groups of trays in the same row to sort two different items to two separate destinations, while also enabling the merging of two trays to carry a larger item for sorting.

Flat Stacking Technology

For folded garments, books, documents, and other flat standard items, products are dropped directly into boxes or bags, typically requiring no additional stacking labor.

Safety Design

Our safety tray design allows for high sorting throughput even at lower sorting speeds with minimal gaps between trays. With no sharp edges and minimal spacing between trays, careful safety precautions eliminate operator concerns.

Reliability

With 17 years of experience in logistics conveyance and automated sorting, RKSORT has a unique advantage in helping clients devise sorting solutions. Our products are renowned for their durability and reliability, making us a trusted partner you can rely on.

Split tray sorters can be widely applied in scenarios requiring high-speed automated sorting of small and medium-sized items, including footwear, books, e-commerce, postal parcels, daily necessities, pharmaceuticals, jewelry, and more.

For certain very small or light items that are difficult for other types of sorters such as cross belt sorters to handle, as well as irregularly shaped items, split tray sorters can easily achieve automated sorting.

Split tray sorters are best suited for processing large volumes of distribution centers directly serving consumers, enabling batch picking and sorting of small products for discrete orders, such as e-commerce goods, retail clothing, omnichannel, third-party logistics, store replenishment, returns processing, and more.

Split tray sorters are not suitable for fragile items that cannot withstand any impact. For sorting such special items, the RKSORT-NBS series sorters from RKSORT can be used.