Roller Conveyor

Roller Conveyor

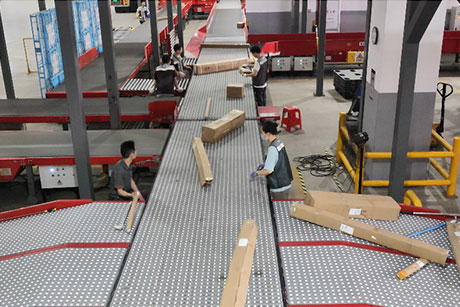

The Realkey Roller conveyor (RKCONV-RC) can be categorized into powered roller conveyors and gravity roller conveyors based on their driving methods. Roller conveyor lines can easily connect and transition with each other, allowing the formation of complex automated logistics conveyor systems when combined with multiple roller conveyor lines and other types of conveyors or specialized machines. RKCONV Roller Conveyors are primarily composed of driving rollers, free rollers, frames, and control system. They are simple in structure, highly reliable, and easy to use and maintain. RKCONV Roller Conveyors are suitable for transporting various items such as boxes, bags, and pallets. For bulk materials, small items, or irregularly shaped items, they need to be placed in containers or on pallets for transport. RKCONV roller conveyors generally come in the following types:

Flat Roller Conveyor

Flat roller conveyors are flexible to use and cost-effective, making them the most commonly used material transport method.

Curved Roller Conveyor

The turning angle of a curved roller conveyor can be set to 30°, 45°, 60°, 90°, 180°, or any other desired angle. The turning radius can be specifically designed according to the plan, allowing the creation of more complex conveyor systems when combined with other conveyor lines.

Center-Aligning Roller Conveyor

Featuring rollers arranged at a certain angle in two rows, center-aligning roller conveyors adjust the position of items to the center of the conveyor line. They are commonly used in the preprocessing section before sorting (usually placed after singulation equipment) or in conveyor sections where the position of items needs to be precisely controlled.

Side-Aligning Roller Conveyor

Side-aligning roller conveyors adjust the position of items to one side of the conveyor line. They are typically used in conveyor sections where precise positioning of items is required during logistics transport.

Accumulation Roller Conveyor

Also known as buffer conveyors, accumulation conveyors allow goods to stop and accumulate on the roller line without significantly increasing the overall resistance of the conveyor system. Accumulation conveyors enable automatic and orderly transmission of items, greatly enhancing production efficiency.

Merge Roller Conveyor

Merge conveyors allow items to be injected into the target conveyor line from different angles, with common merge angles being 45° or 60°. They can form more complex conveyor systems when combined with other conveyor lines.

90° Pop-up Transfer Conveyor

The 90° Pop-up transfer conveyors are typically balanced by four support points and can achieve automatic control for 90° turning of items. In limited space conditions, 90° Pop-up transfer conveyors can achieve 90° turning transport, offering the advantage of space-saving.

For detailed information about the Realkey Roller conveyor (RKCONV-RC), please refer to the product descriptions below or directly contact Realkey customer service representatives.

More +

Swivel Wheel Sorter

Swivel Wheel Sorter

Roller Conveyor

Roller Conveyor

Mini TBC (MINI)

Mini TBC (MINI)

Modular Conveyor

Modular Conveyor

Chain Conveyor

Chain Conveyor

Mobile Van Loader

Mobile Van Loader